With more than 30 years of product, application and industry experience, we understand the needs of heat treatment processes and machinery. Our robust product range of temperature controllers and PID process controllers provide excellent control performance with a wide variety of functionality to suit all budgets. These controllers maintain process variables such as temperature, pressure, flow, and level within the desired range by utilizing control loops.

Our products are designed to monitor and control process variables, ensuring accurate and stable control of industrial processes.

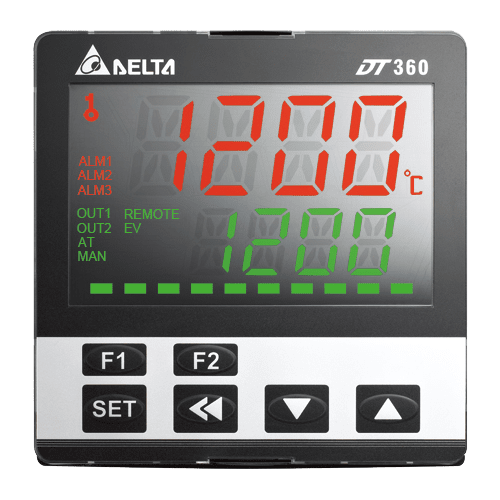

Our most popular models are shown below so have a look and if you have any questions, or require something different, feel free to contact us for friendly help and assistance. We have a controller for every application from leading brands such as West, Delta, Emko, Lumel and CD Automation in single or multi-loop packages and every size format. These controllers allow you to set parameters around a set point, optimizing processes for stable control.

Additionally, our controllers offer system capabilities for various industrial applications, enhancing automation, control, and safety.

Please read our De-mystifying Temperature Controllers or PID Feedback Loop control article written by CD Automation for the PBSI.